Product Description

Product Description

We has been providing genuine and high quality starters at the lowest possible cost in China, and got a high reputation from our clients due to the reliable quality, competitive price and on-time delivery.

1.Durable and high Quality.

2.Nice-looking packing.

3.Prompt delivery.

4.Wide range of parts for more models available.

5.Most competitive wholesale prices.

6.One stop buying service provided.

| car brand | made in China |

| engine type | Diesel engines |

| car model | universal |

| Material | casting |

| type | Machinery |

| installation method | direct installation |

| Scope of application | standard |

| effect | internal combustion engine |

| trademark | OEM |

| ordering method | customized |

| order cycle | 2-5day |

| ignition method | Compression ignition |

| product quality | high quality |

| main market | africa asia |

| Main models | universal |

Product Recommended

Company Profile

Packaging & Shipping

FAQ

1. Is this product new?

All our products are brand new and original, so each product can be strictly tested, please rest assured to buy.

2. Do you offer custom designs?

Custom design is support for customization. We have very rich experience in product customization.

3. Delivery time?

It can be shipped on the same day, special models need to be customized by the factory, we will ship within 15-30 days, without affecting the delivery time. If you have any questions or concerns, please contact us directly for assistance.

4. How to clean the injector?

(1) Remove the injector from the engine;

(2) Connect the carburetor to clean the fuel tank and the fuel injector with a special connector;

(3) Inject the carburetor cleaner into the fuel injector, and check whether the fuel injector leaks when it is not powered on;

(4) Intermittently energize the electromagnetic coil of the fuel injector, let the carburetor cleaner clean the fuel injector, and observe its spray atomization at the same time.

5. How to test the injector?

Detect dripping water from the injector. Select the connector of the tester according to the fuel injector model and connect it well, then check the sealing O-ring group (replace if found damaged), install the fuel injector on the test stand, press the fuel pump button, and adjust the pressure to the vehicle under test Factory specified pressure (preferably higher than 10%), observe whether the injector drips oil. If the leakage is more than 1 drop within 1min (or according to the technical standard), replace the fuel injector.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Three-Ring |

| Hardness: | Soft Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Stepless |

Can spur gears be used in automotive applications?

Yes, spur gears can be used in automotive applications. Here’s a detailed explanation:

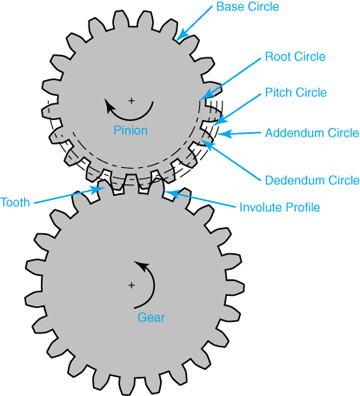

Spur gears are one of the simplest and most commonly used types of gears. They consist of cylindrical teeth that are parallel to the gear axis and mesh with each other to transmit power and motion. While other gear types like helical gears or bevel gears are often preferred in certain automotive applications, spur gears still find their place in various automotive systems and components.

1. Transmissions:

Spur gears are commonly found in manual transmissions, especially in lower gears. They are used to achieve a direct and efficient power transfer between the engine and the wheels. Spur gears in transmissions are designed to handle high torque loads and provide reliable performance.

2. Differential:

In automotive differentials, which distribute power between the wheels while allowing them to rotate at different speeds, spur gears are often employed. They are used in the differential gear train to transfer torque from the driveshaft to the wheels. The simplicity and robustness of spur gears make them suitable for this application.

3. Starter Motors:

Spur gears are commonly used in starter motors to crank the engine when starting a vehicle. They provide high torque and efficient power transmission to rotate the engine’s crankshaft and initiate the combustion process. Starter motor spur gears are designed to handle the initial load and engage smoothly with the engine’s flywheel.

4. Timing Systems:

In automotive timing systems, where precise synchronization of engine components is crucial, spur gears can be used. They are employed in timing belts or chains to drive the camshafts, ensuring proper valve timing and engine performance. Spur gears in timing systems contribute to accurate and reliable engine operation.

5. Accessories and Auxiliary Components:

Spur gears are also utilized in various automotive accessories and auxiliary components. They can be found in power window mechanisms, windshield wipers, power steering systems, and other mechanisms that require controlled and synchronized motion. Spur gears provide cost-effective and efficient power transmission for these applications.

It’s important to note that while spur gears have their advantages, they also have certain limitations. They can generate more noise and vibration compared to gears with helical or bevel tooth profiles. Additionally, spur gears are not as suitable for high-speed or high-torque applications as other gear types.

Overall, spur gears have a significant presence in automotive applications, particularly in manual transmissions, differentials, starter motors, timing systems, and various auxiliary components. Their simplicity, reliability, and cost-effectiveness make them a viable choice for specific automotive gear applications.

What are the advantages and disadvantages of using spur gears?

Spur gears offer several advantages and disadvantages when used in mechanical systems. Here’s a detailed explanation of the advantages and disadvantages of using spur gears:

Advantages of Spur Gears:

- Simplicity: Spur gears have a simple and straightforward design, consisting of cylindrical gears with straight teeth. Their simplicity facilitates ease of manufacturing, installation, and maintenance.

- Efficiency: Spur gears are highly efficient in transmitting power from one shaft to another. They have minimal sliding friction between the gear teeth, resulting in high mechanical efficiency.

- Cost-Effectiveness: Due to their simple design and ease of production, spur gears are generally more cost-effective compared to other types of gears. They are widely available and can be manufactured in large quantities at a reasonable cost.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in parallel or stacked configurations to achieve the desired gear ratios within a confined space.

- High Load Capacity: Spur gears can handle high load capacities and transmit substantial amounts of torque. Their teeth are designed to distribute the load evenly across the gear face, resulting in improved load-bearing capabilities.

- Precision: Spur gears provide precise and predictable motion due to the simplicity of their tooth engagement. This makes them suitable for applications that require accurate positioning and synchronization.

Disadvantages of Spur Gears:

- Noisy Operation: Spur gears can produce noise during operation, especially at high speeds. The engagement of the gear teeth generates impact and vibration, resulting in noise that may require additional measures to mitigate.

- Axial Thrust: Spur gears generate axial thrust forces along the gear shafts due to the parallel arrangement of their teeth. This thrust must be properly managed using thrust bearings or other means to prevent excessive axial loading on the gear shafts.

- Limited Speed Ratio: Spur gears are primarily designed for applications with moderate speed ratios. They are less suitable for high-speed applications due to the limitations imposed by the tooth engagement and potential for increased noise and vibration.

- Unidirectional Operation: Spur gears are typically designed for unidirectional power transmission. Reversing the direction of rotation can cause noise, impact, and increased wear due to the abrupt change in tooth engagement.

- Prone to Wear: The sliding contact between the gear teeth in spur gears can result in wear over time, especially under heavy loads or inadequate lubrication. Regular maintenance and proper lubrication are necessary to minimize wear and extend gear life.

It’s important to consider these advantages and disadvantages when selecting gear types for specific applications. While spur gears are well-suited for many applications, other gear types, such as helical gears or bevel gears, may be more suitable in certain situations depending on the requirements and operating conditions.

What are the benefits of using a spur gear mechanism?

Using a spur gear mechanism offers several benefits in various applications. Here’s a detailed explanation of the advantages of using a spur gear mechanism:

- Simplicity: Spur gear mechanisms are relatively simple in design, consisting of cylindrical gears with straight teeth. Their simplicity makes them easy to manufacture, assemble, and maintain. They have fewer components compared to other types of gear mechanisms, resulting in lower complexity and potentially reduced costs.

- Efficiency: Spur gears exhibit high efficiency in power transmission. The teeth of spur gears mesh directly, resulting in minimal energy loss during transmission. The simplicity of their tooth profile allows for efficient power transfer, making them an energy-efficient choice for many applications.

- Compactness: Spur gears have a compact design, making them suitable for applications where space is limited. They can be arranged in-line, parallel to each other, or at right angles using additional components such as bevel gears. This flexibility in arrangement allows for efficient power transmission in tight spaces.

- Versatility: Spur gears are versatile and can be used in a wide range of applications. They are available in various sizes, configurations, and materials, allowing them to be tailored to specific needs. Spur gears can handle different torque and speed requirements, making them suitable for both low and high-speed applications.

- High-Speed Capability: Spur gears can achieve high rotational speeds due to their straightforward design and direct tooth engagement. They are capable of transmitting power efficiently at high speeds, making them suitable for applications that require rapid motion or high rotational velocities.

- Precise Positioning: Spur gears provide accurate positioning due to their precise tooth engagement. The straight teeth allow for precise control of rotational motion, making them suitable for applications that require precise positioning, such as robotics, machinery, and automation systems.

- Cost-Effectiveness: Spur gears are often cost-effective compared to other gear mechanisms. Their simple design and ease of manufacturing contribute to lower production costs. Additionally, their high efficiency helps reduce energy consumption, resulting in potential long-term cost savings.

- Reliability: Spur gears are known for their reliability and durability. The direct tooth engagement provides excellent load distribution, minimizing stress concentration and wear. When properly lubricated and maintained, spur gears can operate reliably for extended periods, making them suitable for demanding industrial applications.

- Wide Availability: Spur gears are widely available in the market, with various sizes, materials, and configurations to choose from. This availability ensures easy sourcing and replacement of gears when needed. Additionally, spur gears have been used for many years and have a well-established design and manufacturing process, leading to a robust supply chain.

These benefits make spur gear mechanisms a popular choice in numerous industries, including automotive, machinery, robotics, aerospace, appliances, and more. Their simplicity, efficiency, compactness, versatility, and reliability contribute to their widespread use in a wide range of applications.

editor by CX 2024-03-27